TEMISTh poursuit ses travaux de recherche sur la gestion thermique appliquée à la conversion de puissance. Face à la miniaturisation des dispositifs électroniques et à l’augmentation des densités de puissance, la dissipation efficace de la chaleur devient un enjeu majeur pour garantir la fiabilité et la performance des systèmes.

Une Recherche de Pointe au Service de l’Électronique de Puissance

Conception et Simulation Numérique Avancées

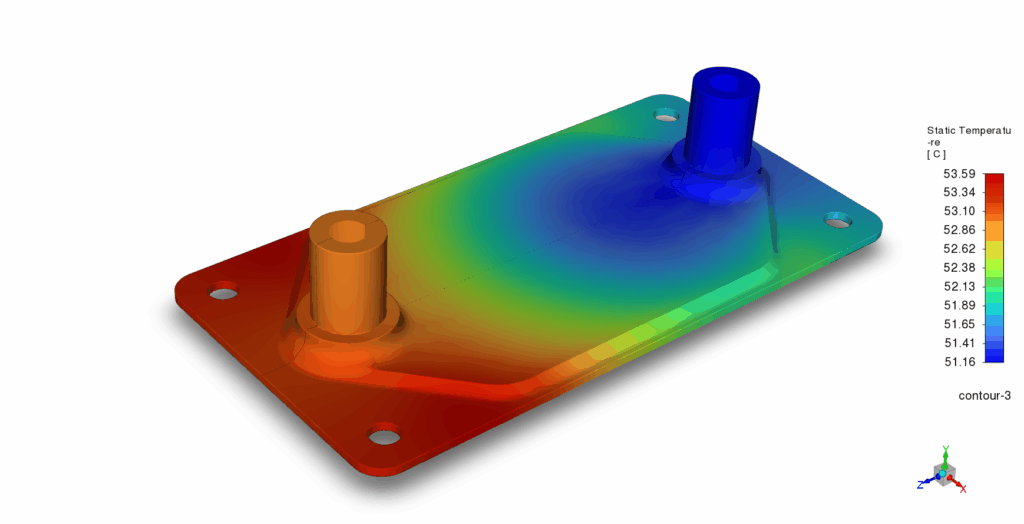

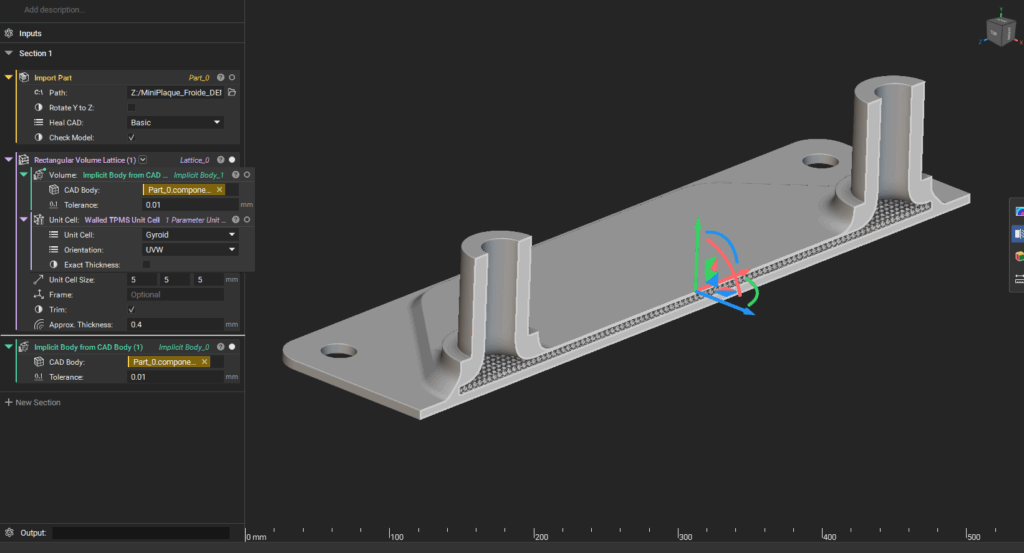

L’équipe de TEMISTh s’est spécialisée dans la conception de dissipateurs thermiques en cuivre de très faible épaisseur, adaptés aux contraintes d’encombrement des convertisseurs de puissance modernes. Grâce à des outils de simulation numérique avancés, les chercheurs optimisent la forme, la structure interne et la répartition du flux thermique afin de maximiser l’efficacité du refroidissement tout en limitant la perte de charge hydraulique.

Fabrication Additive : Vers des Géométries Sur-Mesure

Pour répondre à ces défis, TEMISTh mise sur la fabrication additive (impression 3D métallique) du cuivre. Cette technologie permet de réaliser des dissipateurs aux géométries complexes, impossibles à obtenir par les procédés conventionnels, tout en conservant une épaisseur minimale. L’impression 3D ouvre la voie à la personnalisation des échangeurs thermiques, adaptés aux besoins spécifiques de chaque application.

Prochaines Étapes : Caractérisation Expérimentale

Afin de valider les performances de ces nouveaux dissipateurs, TEMISTh s’apprête à lancer une campagne d’essais expérimentaux. Les tests porteront sur la mesure de la résistance thermique et de la perte de charge en fonction du débit de fluide caloporteur. Ces données permettront d’affiner les modèles de simulation et d’optimiser encore davantage les solutions proposées.

Conclusion

En combinant conception assistée par ordinateur, simulation thermique, fabrication additive et caractérisation expérimentale, TEMISTh s’impose comme un acteur clé de l’innovation dans la gestion thermique des systèmes de conversion de puissance. Les résultats attendus ouvriront la voie à des dispositifs plus compacts, plus performants et mieux adaptés aux exigences de l’électronique de demain.

Suivez nos actualités pour découvrir prochainement les résultats de ces essais et les nouvelles avancées de TEMISTh !