Presentation of our liquid-air Test Loop

Temisth is specialized in the design of thermal systems.

Our skills on CFD numerical tools allows us to significantly improve the performance of heat exchange applications by creating intensification structures for the heat exchanges, adapted to your requirements.

These geometries, which are often complex, require the use of innovative manufacturing processes such as metallic or plastic additive manufacturing. However, this process can lead to performance biases of the manufactured heat exchangers due in particular to problems concerning the roughness or the effective thermophysical properties.

It is in this context that Temisth created in November 2019 a testing service whose objectives are::

- Validation of key points of our numerical models

- Validation of innovative heat exchanger concepts and thermal systems

- To guarantee the quality and reliability of the produced parts (ensure the absence of critical defects) in addition to the functional performance

- To increase the level of maturity of concepts, as close as possible to operational conditions

Instrumentation and connectors of a tested exchanger

Personalized tests for your project

Each industry has unique standards and performance requirements, so we tailor our test methods and procedures to your specific needs (instrumentation, size, test scenario, etc.). This modularity ensures that the overall objectives are met.

Thanks to our own additive manufacturing facilities, we are able to tailor-made input and output connectors for the exchanger to facilitate its installation on the test loop.

An air-liquid test loop

After a first cold plate test bench installed one year ago, we present here our second test bench designed to test air – liquid heat exchangers and whose origin was the performance tests of the HEWAM heat exchanger (“Heat Exchanger With Additive Manufacturing”) in the continuation of the partnership with PrintSKY (joint venture AddUp – Sogeclair aerospace) that we presented at the Bourget 2019 event.

https://temisth.com/hewam-heat-exchanger-with-additive-manufacturing/

Hewam heat exchanger exposed on Sogeclair aerospace booth at Paris Air Show 2019

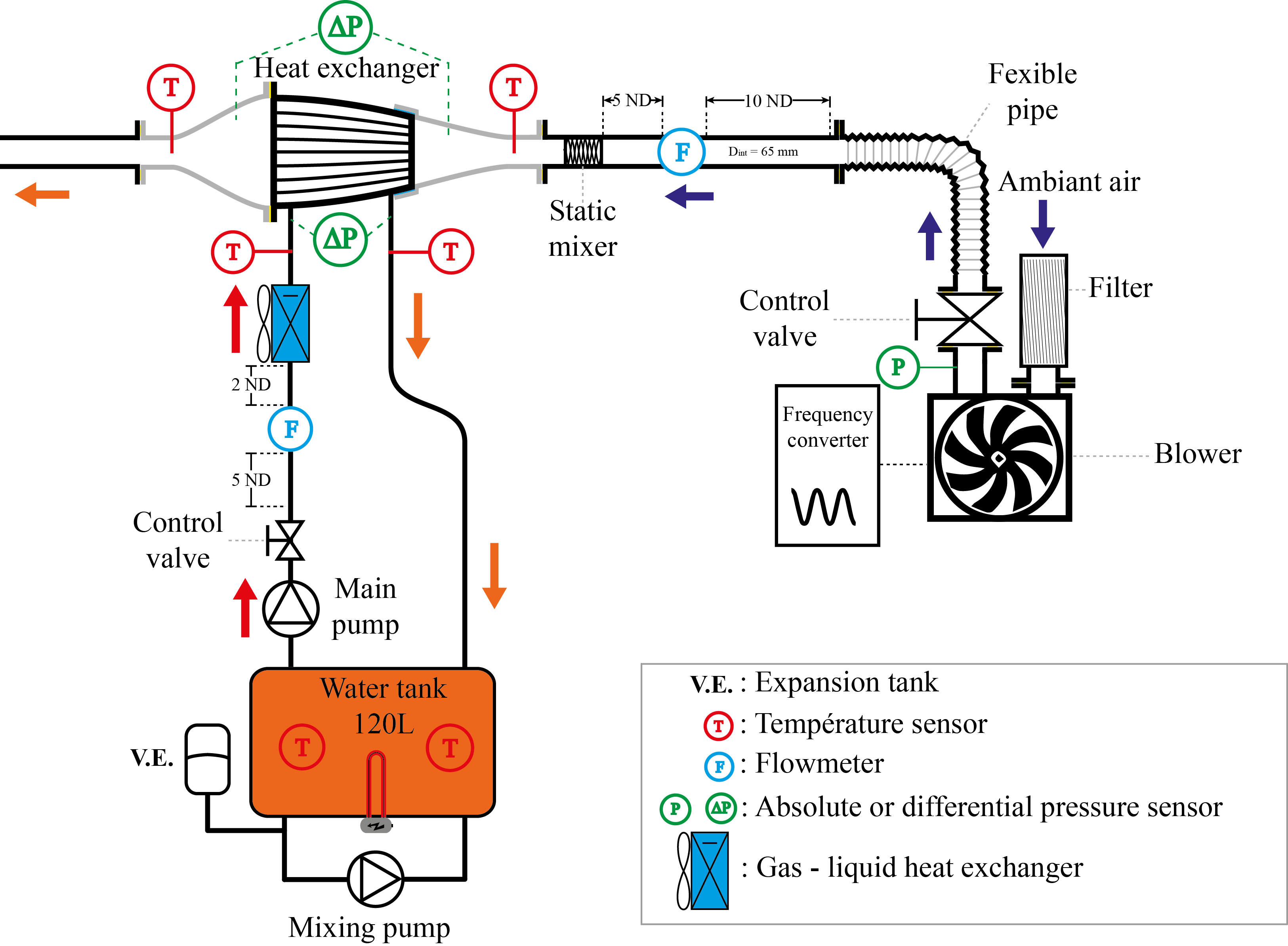

This experimental test loop, completely developed internally, can reproduce the boundary conditions of an air-liquid exchanger. Its complete instrumentation allows us to collect the experimental data necessary to characterize the performance of the tested exchanger and to ensure the operation of the control system. A diagram and photo of the bench are shown below.

Operating ranges

Liquid

- Temperature range : 20°C to 80°C

- Maximum flow rate: 2 kg/s

- Variable pressure from 1 to 5 bars

- Maximum ΔP: 800 mbars

- Maximum thermal power: 9 kW

Air

- Temperature range : today ambient temperature, soon hot air (around 80°C)

- Maximum flow rate: 0,15 kg/s

- Operating pressure : atmospheric pressure

- Maximum ΔP: 250 mbar

Instrumentation and precision acquisition systemIn the near future, air humidity monitoring will be implemented.

The use of precise and regularly calibrated sensors (temperature, heat flux, flow rate, pressure, differential pressure, electrical measurements) permits a reliable characterization of the thermo-hydraulic performance of the exchangers.

A programmable controller with acquisition modules ensures data recording.

Regulation, a guarantee of the quality of measures

We develop our own control devices allowing us to control the various variables of the thermo-hydraulic and aeraulic loops and to carry out tests according to fixed scenarios.